|

|

|

||

| Vacuum

creating systems 1) based on vacuum hydrocirculating units 2) based on steam ejectors |

||

|

Jet compression units for flare and low-pressure gases recovery 1) based on two-phase jet devices 2) based on steam ejectors | ||

| Jet

absorption gas cleaning units for hydrocarbons removal from breathing gases and oil and petroleum products gases recovery |

||

| Jet

devices ejectors and injectors for various purposes |

|

|

Technovacuum Ltd. +7 (495) 956-76-21 +7 (499) 261-99-98 +7 (499) 267-82-03 Russia, 105082, Moscow B.Pochtovaya str., 26 "B", build.2, 5-th floor, office 1, room 11A |

||

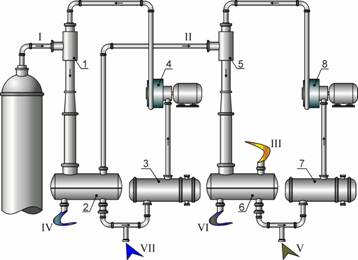

Layout of

the two-stage VHC unit

|

|

1 - vacuum creating device 2,6 - separators 3,7 - heat exchangers 4 - pump for motive liquid (diesel fraction, gas oil) 5 – compressor jet device 8 - pump for motive liquid (sorbent of acid gaseous admixtures) I - gas-vapor mixture from distillation column II – gases for additional compression and cleaning from acid components III – gas into fuel header IV – motive liquid excess withdrawal line V – feed of regenerated sorbent VI – discharge of sorbent for regeneration VII – fresh motive liquid makeup line |

At this layout the hydrocarbon motive liquid (diesel fraction or gas oil) is used at the first compression stage and the acid gas sorbent (e.g., monoethanolamine solution) acts as motive liquid at the second stage. This allows to remove hydrogen sulfide from cracking gases simultaneously with their compression.